Please contact us on

07760467830

&

via whats app

We offer the complete

manufacturing package

Camper van & motor home

seat bed systems

plus general fabrication services

please see our services below

TUV ECE R 14.09-145-16-17

Why We Do It!

FWX DIRECT wanted to change the face of modern fabrication. We also wanted to relight the passion for the skills and industry that were slowly disappearing. To do this our mission was to build a micro workshop that had full in-house capabilities. Please see below the processes we can offer .

What we do

Multiple manufacturing processes under one roof

From 2017 we have pushed the safety standards of Vehicle Occupant safety and in doing so have developed our own product range to fit most vehicles worldwide. These are covered across our ranges IMMIX, MIKADO & BENCHI

Laser cutting services

3Kw fiber laser cutting machine

With this piece of kit we can cut all types of metals to precise tolerances. This also has a large cutting area of 3000x1500mm

With 2 cutting tables this is extremely quick which keeps our lead time to a minimum

Press brake bending

We have 2 CNC press brakes

1. is a 1200mm long 50ton machine which is excellent for all parts and high volumes

2. is a 3000mm 100ton machine which is a monster and is also aided by 3D CAD bending software

Welding

& fabrication

6 bays in total, 1 being a Tig & Jig bay for one off and prototype work. The other 5 are Mig welding bays fully integrated and organized with individual tools and jigs. All welding machines are high output. We also have a semi automatic cold saw and a large bed pedestal drill

CNC wood routing

Our large capacity router machine also has a bed size of 3000x1500mm with vacuum suction and extraction systems. This makes light work of the 12mm ply wood upholstery templates we cut on a daily basis

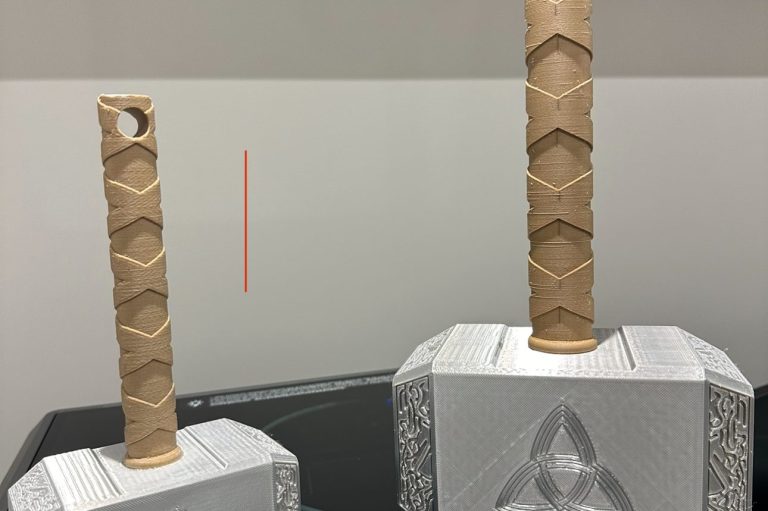

3d Printing & prototype

design

3d printing is now very popular but also a key tool for us to have onsite to make changes / new product add ons & also help customers with their own prototyping

Powder coating

After making our own products we need to also finish them. We have a large electric oven & spray booth to bake off our powder coated parts. We also have customers bring parts for us to finish for them and assemble / pack. This is what gives us the edge over our competitors

Assembly

&

worldwide

delivery

We have 3 final assembly bays complete with separate tools and storage areas

GLOBAL, We have customers all over the globe and also distributors in the USA , Germany and even Australia. With our network we can ship anywhere